Risks Associated With Post-Weld Heat Treatment

by Admin

Posted on 12-09-2023 05:14 PM

A. What is post weld

heat treatment

?

this is a process commonly referred to as stress relief, so called because it is carried out at temperatures at which yield strength has fallen to a low value. If the structure is heated uniformly, the yield strength of the material around the weld is unable to support the initial deformation. Creep occurs at the elevated temperatures and strain will occur by a diffusion mechanism, relaxing the residual stresses even further.

The extent to which residual stresses are relaxed will depend on temperature for any given material and on material for any given temperature.

The extent to which residual stresses are relaxed will depend on temperature for any given material and on material for any given temperature.

Q: i work for a small fab shop and i am beginning the process of earning my cwi. I don’t have any formal technical training, but i am interested in understanding the behaviors of filler metals when subjected to heat treatments. I’m not clear on why there are different yield, tensile strength, and charpy properties of filler metals depending upon if they were heat treated or in the as-welded condition. Can you shed some light on this? a: excellent! earning your certified welding inspector (cwi) will be great career move and will benefit the company you work for. Stress relieving, or more commonly referred to as postweld heat treat (pwht), is a type of heat treating performed on the weld to reduce the residual stress caused by welding.

By evelyn mae most of us have seen welding being performed at some point in our lives, whether it was a repair job or the construction of a new structure. What we might not know is that the welding process itself can create issues that could lead to unexpected failures and even cause disasters. That’s where post-weld heat treatment comes into play. It is a procedure that has been used in the welding industry for decades to minimize the risks of failure by improving the strength and durability of welded joints. Post-weld heat treatment is a crucial procedure for a wide range of applications in various industries such as automotive, aerospace, oil and gas, and many more.

What is Meant by Post Weld Heat Treatment?

A post weld heat treatment is a process that involves elevating the temperature of a material or materials following a welding process. A post weld heat treatment is performed to alleviate residual stresses, increase the strength, increase or decrease the hardness, and reduce the risk of cracking. An array of heating processes can be used to carry out post weld heat treatment.

Comment 5 | share | tweet | share | pin it | print | email have you heard of post weld heat treatment (pwht)? of course you have. If you are involved in welding you have definitely heard this term. But what is phwt? when is pwht required? what temperature should pwht be done at? heat treating of materials can be a very complicated subject, but when it comes to heat treatment after welding it boils down to a simple concept: pwht is done in order to maintain or improve material strength and mechanical properties and to relieve residual stresses.

Different materials, when subjected to the same thermal cycle, can potentially have significantly different results on the materials. Heat treatments are

What is a Postweld Heat Treatment in Welding?

the following tables and lists give 4340 alloy steel datasheet and specification including chemical composition, physical properties and mechanical properties, heat treatment, welding, etc.

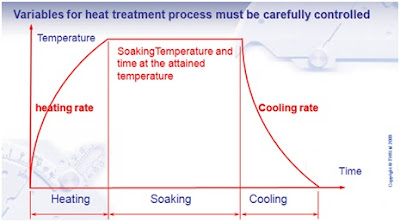

Pwht - short for post weld heat treatment - is the more familiar and international name for what is also known as low-stress annealing. Such heat treatment is often used to minimize thermal stresses in the steel after welding. In some projects, this process itself is a requirement. What exactly is pwht? before we go further into the technical specifications, it is useful to know what exactly pwht is. Simply translated, it is a heat treatment performed after welding operations. The treatment consists of a controlled process in which the workpiece is heated to a certain temperature and held. The heat changes the properties of the workpiece material, such as the force that can be applied to it.

When welding some base materials and for some service conditions, preheating and/or post-weld heat treatment may be a requirement. These types of thermal treatments are required to ensure suitable weld integrity and will typically prevent or remove undesirable characteristics in the completed weld. Any form of heat treatment is costly since it demands extra equipment, extra time, and extra handling. For these reasons, heat treatment should only be undertaken after careful consideration of the advantages it may offer. In certain cases, heat treatment will be mandatory, as with heavy sections of low alloy steels, whereas in other cases, it will be a justifiable precaution against early failure in service.